- 5-axis Hermle CNC milling centers (C52, C42 and C22 – for electrode production)

- 3-axis DMG Eco Line CNC milling center

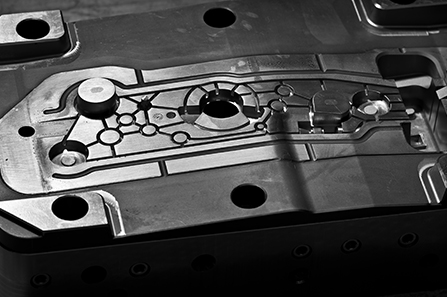

- SODICK AG 60L, AG 100L electric discharge machines

- SODICK ALC 600G wire electric discharge machine (AQ 1500L from March 2018)

- Classical machines (TOS FNGJ 32 mill, SU50A lathe, ARG 330 plus belt saw, BPH 20NA grinder)

- Manual workplace equipment – threading machine, blasting machine, bench drills, etc.

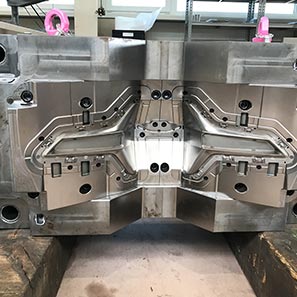

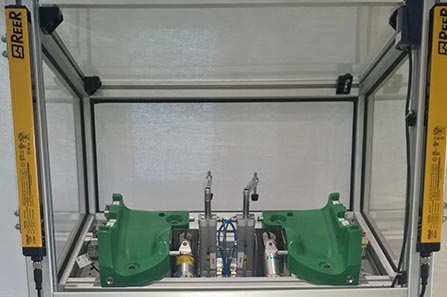

Our own tool shop

At the foundation of our company we knew that one of the main milestones on the path to success would be building our own tool shop. This is because our main business activity – the production of plastic parts – is closely linked to the production of injection molds. Producing tools and jigs at our own cost brings not only great financial savings, but also greater flexibility as for customer requirements and independence from the capacities of external tool shops. Furthermore, it supports trouble-free running of the plastic molding plant.

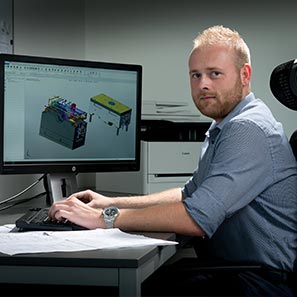

Tool development and design

Support for development, plastic part fabricability analysis, designing injection molds and jigs

Our work includes assessing the fabricability of plastic parts, designing the optimum production process and subsequently designing an injection mold or various measuring and inspection jigs.22

When designing these tools, we focus especially on trouble-free functioning in mass production and at the same time a long lifetime with easy maintenance with regard to efficient production adhering to the set deadline and price.

We have experience in designing various types of injection molds for plastic parts intended for both technical and decorative uses.

We use Catia V5, Solidworks 2017 and ZW3D CAD software for these activities. We are also able to receive data from NX CAD software. In more complicated applications, we simulate and analyze creep to detect common risks and specify the concept of the mold in detail.

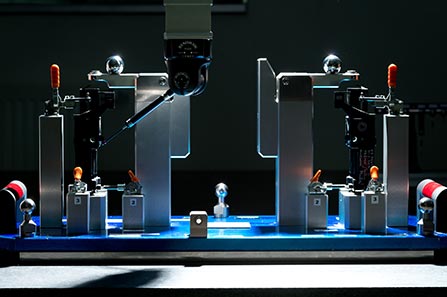

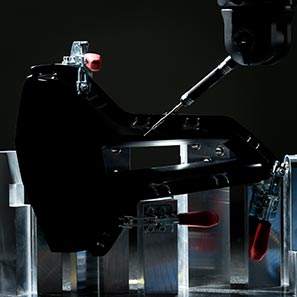

Machine equipment

We have the most modern technologies currently available in the market.

Production program

WIDE PRODUCTION PORTFOLIO

In addition to our main business activity, which is the production of mass injection molding tools, we are able to produce prototype tools, measuring and assembly jigs as well as implement customized and small-series production.

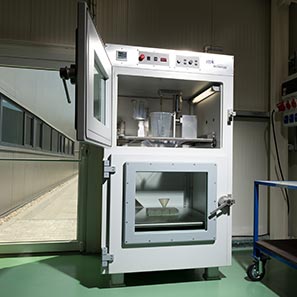

Quality inspection

To inspect dimensions and evaluate production processes, we are equipped with the most modern measuring devices, such as a 3D ZEISS ACCURA II 10 measuring device, a digital linear height meter, digital calipers, digital micrometer gauges, a digital depth meter, digital deviation meters, digital deviation meters with arms for inner measurements, internal gauges, thread gauges, cavity gauges, sets of end gauges, roll gauges, machine measuring probes, etc.

I am interested in the service